Power2E

Power electronics expertise

Power2E is a design office specializing in the design of power electronics systems, from simple functions to complex architectures.

We support our customers at every stage of their project, offering feasibility studies with realizations, technical expertise and design assistance.

Our mastery of demanding environments (high-temperature, high-voltage, high-power) and technical PCBs enables us to develop high-performance solutions tailored to the most demanding industrial needs.

Supporting You at Every Step

Analyze

We analyze your specifications to understand your precise expectations and constraints. This step enables us to define the performance, environment and requirements of your power electronics project.

Define

We design the system architecture, selecting the most appropriate technologies and components. This step guarantees an optimized solution in terms of performance, cost and reliability.

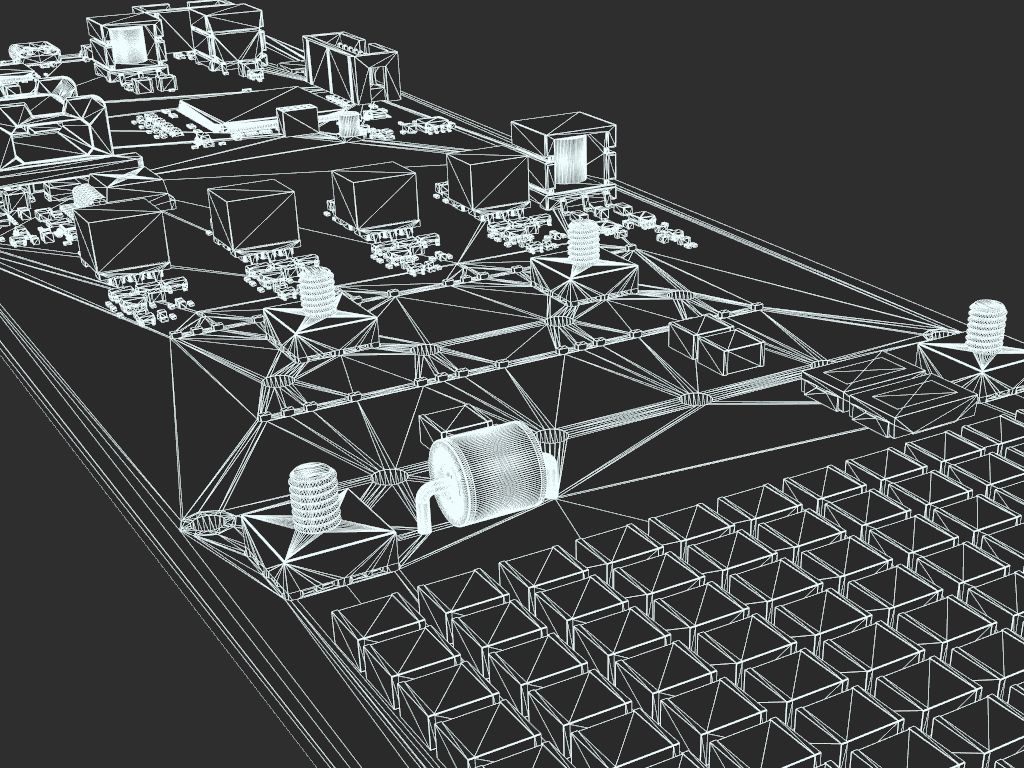

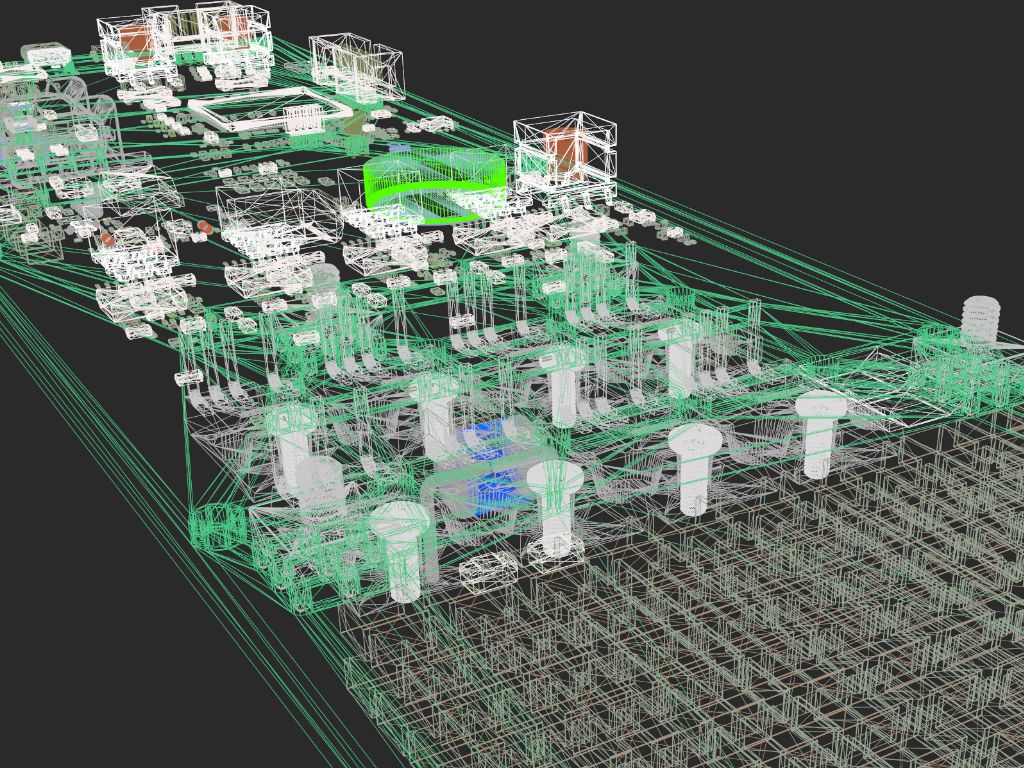

Simulate and Design

Using advanced simulation tools, we validate the system’s electrical and thermal behavior. We then create the schematics and routing for the printed circuits, in compliance with industrial standards and constraints.

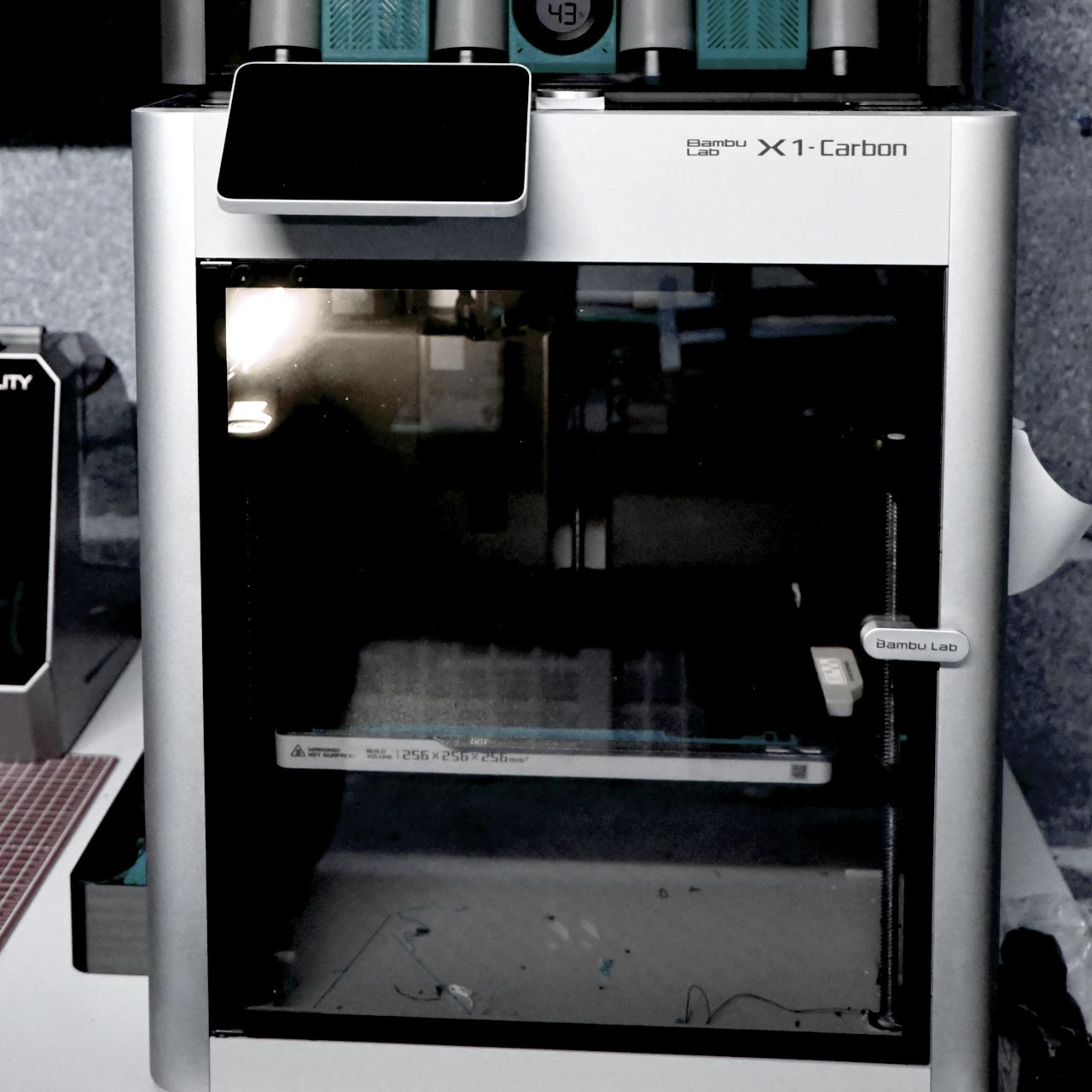

Assembly

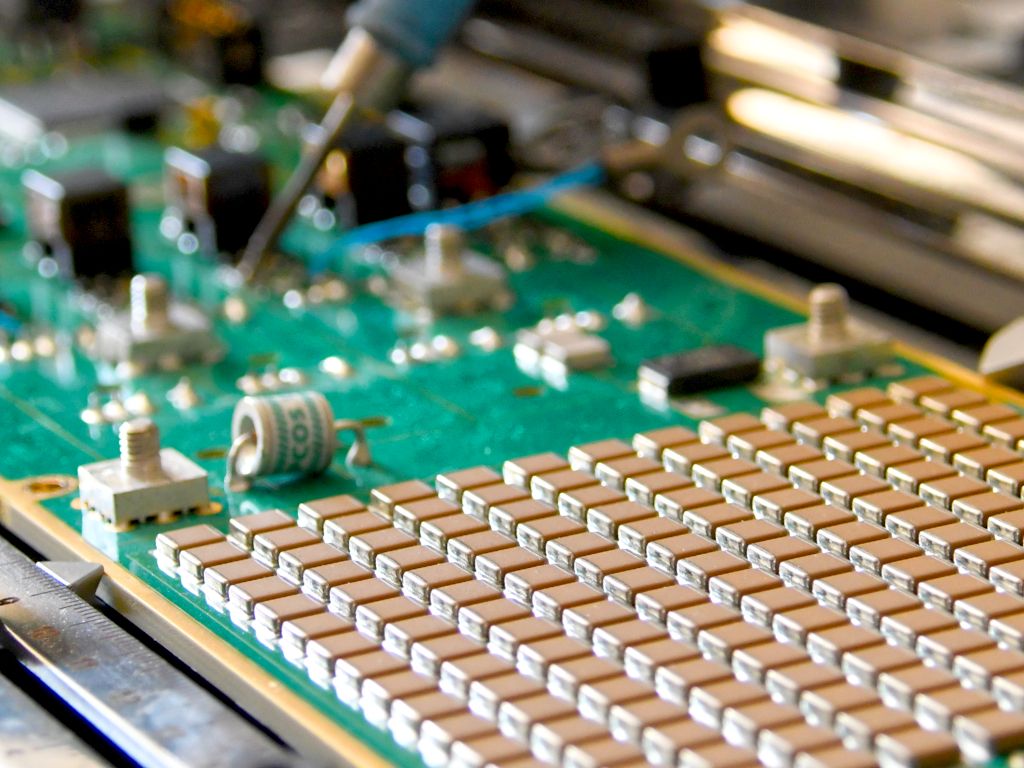

Assembly of our prototypes is carried out in-house, enabling us to check the correct integration of components. This approach ensures that we can anticipate any difficulties and, if necessary, draw up precise assembly procedures.

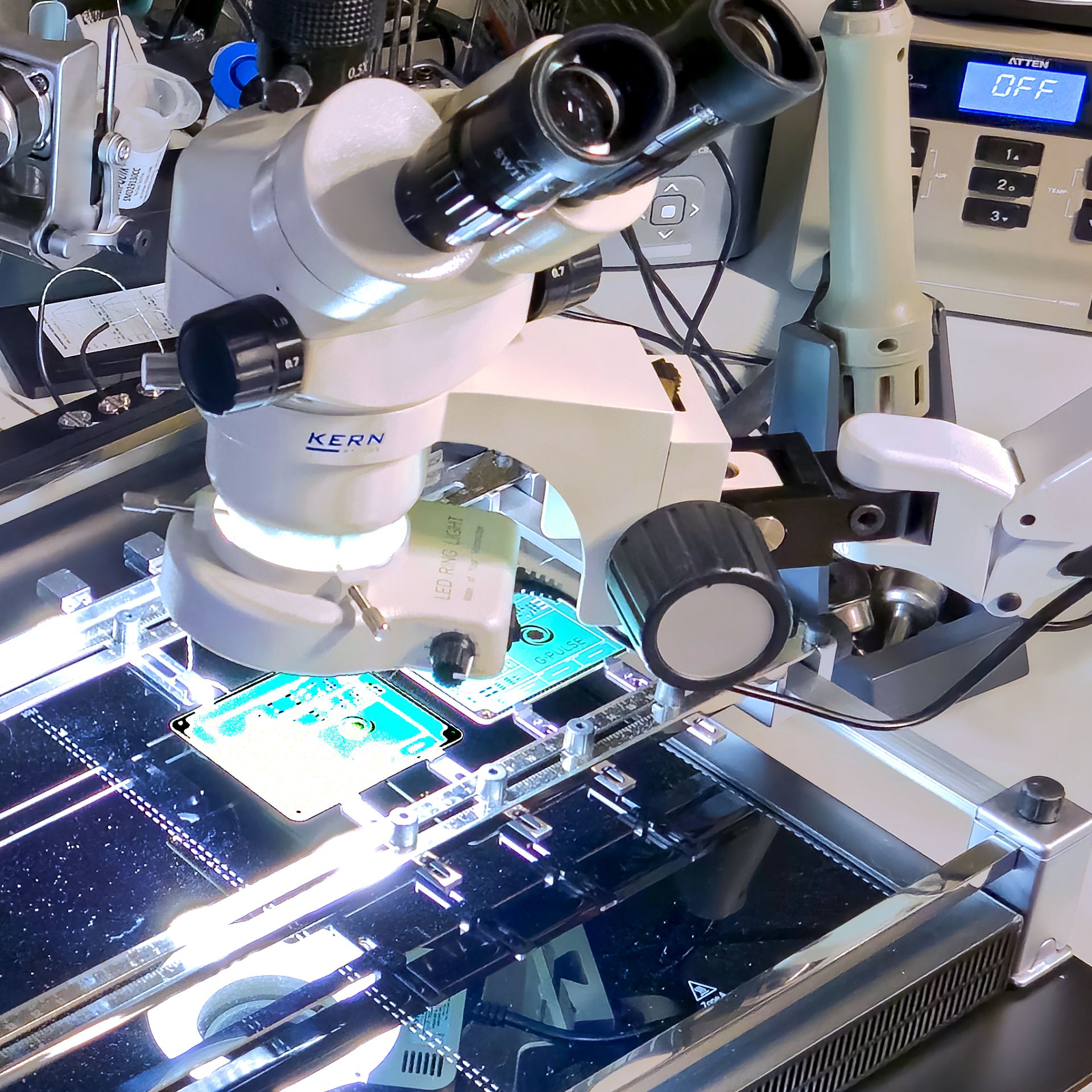

Prototype

We tune-up and validate the prototype. This phase guarantees a functional prototype before the product’s industrialization.

Our expertise

Extreme environments

Our power electronics engineering department designs your innovative solutions for extrem environments. We master high temperatures, with systems capable of operating above 200°C, as well as high voltages up to 40 kV. Our designs incorporate high power ratings, in excess of 10 kW, while guaranteeing reliability and performance.

Technologies

We design and optimize all types of power conversion topologies, AC/DC, DC/DC and DC/AC. We master both insulated and non-insulated architectures. Depending on performance and space requirements, we integrate wound (traditional) or planar (compact and optimized for high frequencies) magnetic components.

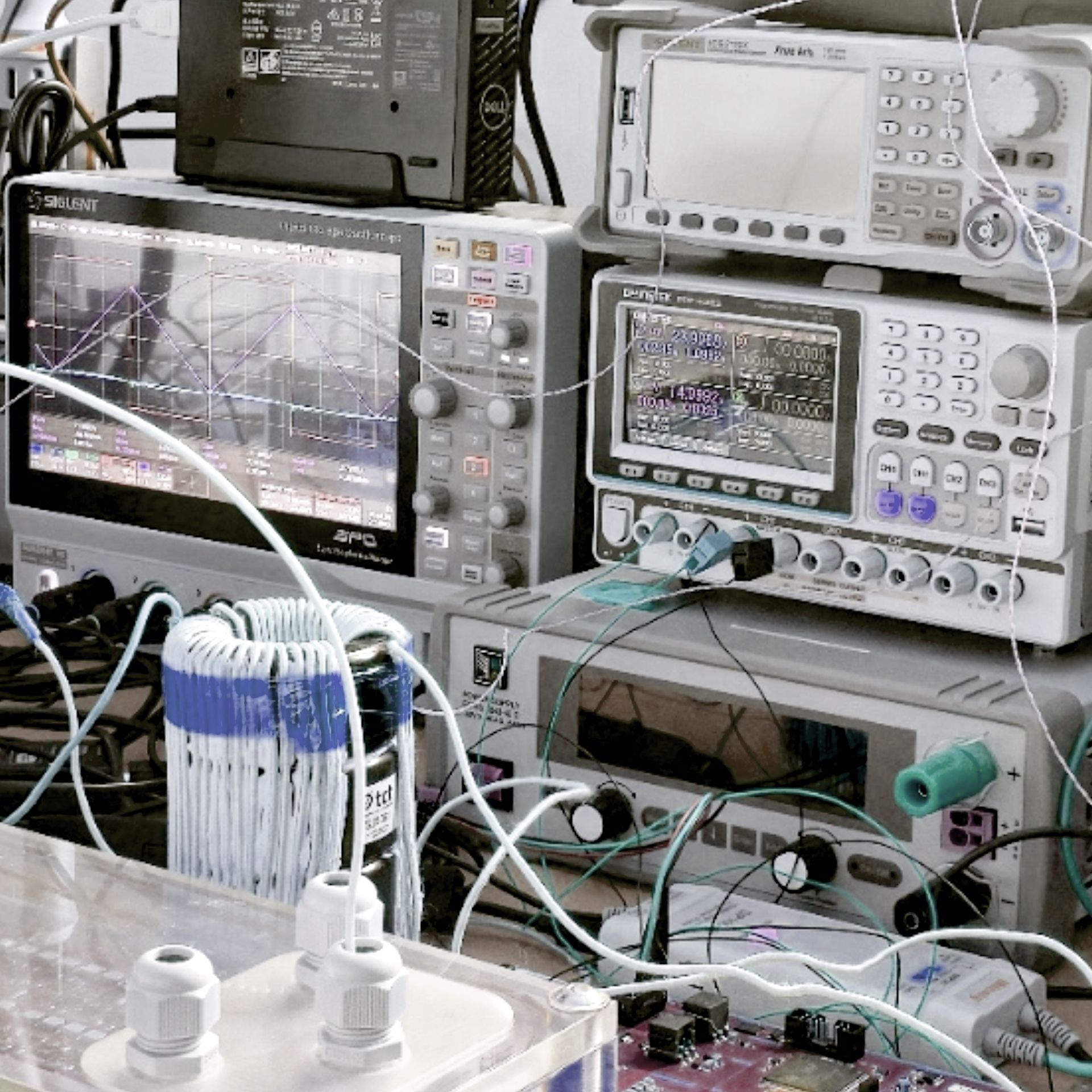

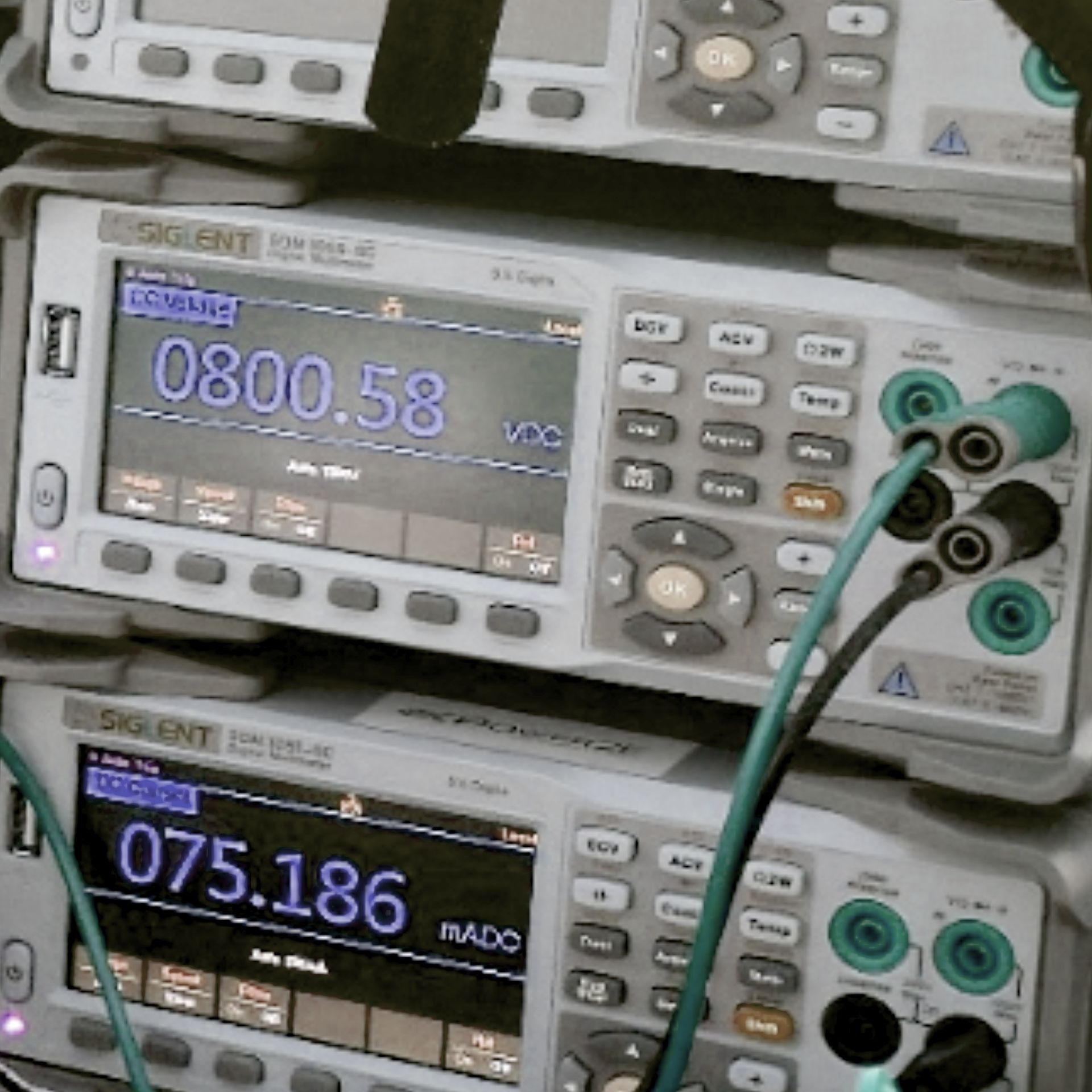

Test and validation

At Power2E, we have all the equipment needed to assemble, tune-up and validate prototypes, guaranteeing reliable, optimized developments. This expertise enables us to support our customers during the industrialization phase, ensuring a smooth transition between design and production. To improve test reproducibility and efficiency, we automate our measurement benches, ensuring precise and rigorous control of prototype performance before final delivery.

Data security

The security and confidentiality of our customers’ data is a top priority. All information and technical files are stored in-house on secure servers, guaranteeing controlled and protected access. To ensure data integrity, backups are made on a daily basis, enabling information to be restored in the event of an incident and ensuring optimum project continuity.

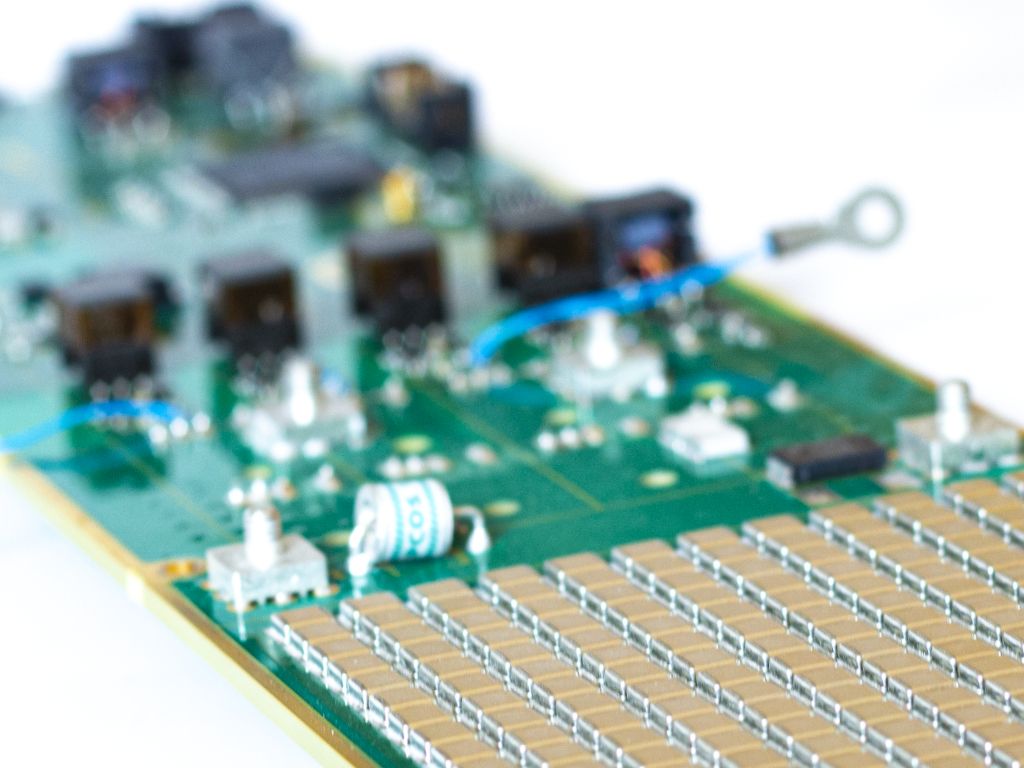

We produce technical PCBs adapted to extreme constraints: laser vias for optimized interconnection, flex/rigid circuits, high current density, BGA and SMI integration, including multilayer. Our printed circuits incorporate thick copper layers to withstand high currents. Thanks to a network of specialized subcontractors, we can guarantee top-quality manufacturing that meets the industry’s most stringent requirements.

Markets

Industry

Power electronics are essential for improving the energy efficiency and reliability of industrial equipment. We have the capacity to design solutions for motorization, energy management and power supply for automated systems, while meeting performance and robustness requirements.

Energy

Whether for the power grid, renewable energies, energy storage, geothermal energy or the oil industry, power electronics help optimize energy conversion and distribution. We are able to develop solutions adapted to harsh environments, guaranteeing high reliability in extreme conditions.

Aeronautic

Compactness, efficiency and reliability make power electronics a key component of aeronautical on-board systems. We have the expertise to design converters and power supplies that meet the stringent weight, efficiency and safety constraints specific to this field.

Defense

Military applications require conversion and power supply systems capable of operating under extreme conditions. We have the expertise to develop robust, safe solutions that meet the most stringent standards in terms of reliability, resistance to shock, vibration and temperature variations.

Standards / Approvals

IPC-2221

We have mastered the IPC-2221 standard, which defines the general rules for printed circuit board (PCB) design. This standard covers all requirements relating to materials, layout, spacing, vias, as well as thermal and electrical considerations, guaranteeing reliable and robust designs. Thanks to this expertise, we are able to design PCBs that comply with industry standards, ensuring optimized manufacturing, compatibility with assembly processes and durability in demanding environments.

Afnor SPEC 2212

We have mastered AFNOR SPEC 2212, a specification dedicated to printed circuit board design rules. It defines optimal routing parameters to guarantee PCB manufacturability, reliability and performance, taking into account technological and industrial evolutions. Thanks to this expertise, we are able to design PCBs to modern standards, facilitating their industrialization and ensuring their compliance with production and assembly requirements.

DO-160

We have mastered the DO-160 standard, which defines the environmental requirements for on-board electronic equipment in aeronautics. It covers many aspects, such as vibration, extreme temperatures, humidity, electromagnetic interference (EMI/EMC) and mechanical stress. Thanks to this expertise, we design electronic systems capable of operating in demanding environments, guaranteeing their compliance with aeronautical standards and their robustness under operational conditions.

CIR accreditation in progress

We have applied for Crédit d’Impôt Recherche (CIR) accreditation, which will recognize our ability to carry out research and development in line with the requirements of the tax authorities.This approval will enable our customers to benefit from a tax advantage by deducting part of the expenses incurred for their innovation projects. Thanks to this approval, we will be able to offer high-level technical support while optimizing development costs for companies investing in innovative power electronics solutions.